|

|||||||||||||||

| Group5: | 6 blaze gratings having periods of 10µm, 20µm… to 60µm: Each grating has 4 periods, and has 20 gray levels in each period. D = 0.12 + 0.0526i, where i = 0, 1, 2 . . . . . 19. |

| Group 6: | 6 blaze gratings having periods of 50µm, 100µm, 200µm, 300µm, 400µm, and 500µm: Each grating has 4 periods, and has 100 gray levels in each period. D = 0.12 + 0.0101i, where i = 0, 1, 2 . . . . . 99. |

| Part III: | With this portion of the calibration

plate, HEBS-glass users can determine the optical density (OD) range of

a gray scale mask that is most appropriate for a particular device fabricated

with existing in-house processes and equipment for photolithography and

ion beam etching. This part contains two sets of test patterns that

are arranged as follows:

|

| Each of the two

test patterns has nine optical density ranges. There are 20 gray

levels within each of the nine optical density ranges. Within the

test pattern on the left, the 20 OD values in each of the nine ranges vary

in intervals of constant delta OD. The test pattern on the right

has the same optical density ranges but vary in intervals of a constant

delta T.

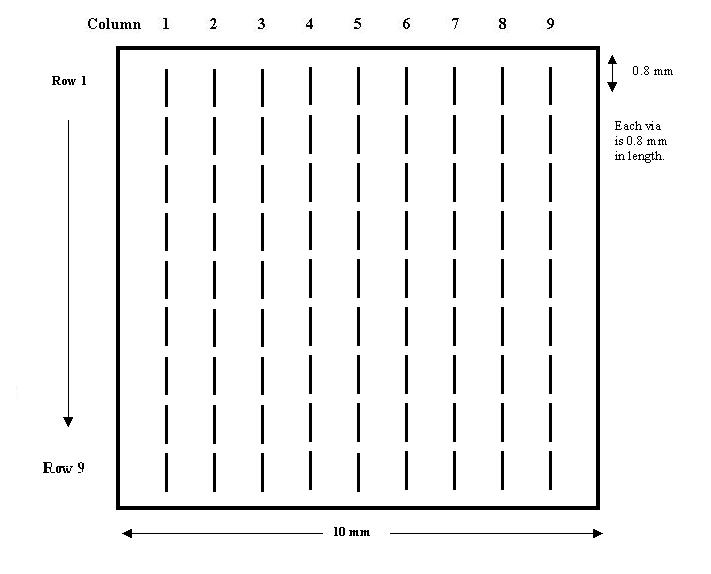

Each test pattern is composed of a 9x9 array of via structures that are 800 microns in length (See Diagram I). The OD range is consistent across a row, whereas the width and gap of the via structure is consistent down a column. Table I exhibits the values of minimum and maximum OD’s within each of the nine OD ranges. Table II displays the dimensions of the via structures within a column. Diagram 2 defines the via gap and via width. Note that when the via gap is 0 µm, the via structure is actually a V-groove. For more detailed reference, the OD values corresponding

to the twenty gray levels in each of the nine rows for test patterns of

constant delta OD is listed in Table III. Similarly, the OD values

of the twenty gray levels in each of the nine rows for test patterns of

constant delta T is listed in Table IV.

|

|

| Instructions

for viewing mask patterns under an optical microscope: Please

view mask patterns in the HEBS-glass under a microscope in transmission

mode (i.e. using the bottom light); the mask pattern has little or

no contrast in a reflection mode (i.e. using the top light) because the

reflectance of HEBS-glass is 4% in both clear and e-beam darkened areas.

Instructions for handling and storage:

Since the mask pattern is inside the glass, HEBS-glass masks can be washed

like a quartz glass substrate, using any solvent or acid (except HF).

HEBS-glass masks should be kept at room temperature. Humidity levels

from 0 to 100% do not affect HEBS-glass masks.

|

|

| Diagram 1. Layout of one test pattern

|

|

Next Page |

|

Company | Technology | Products | Online Help | Contact