|

|||||||||

LDW-GLASS PHOTOMASK BLANKS |

|

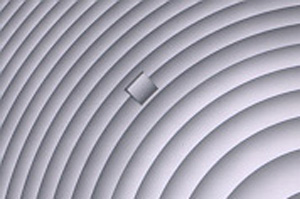

DOE FABRICATION: 3D SHAPING A small positive lens within a negative lens The range of resist thickness in the depth versus optical density calibration curve is flexible, as seen in Fig. 1 and Fig. 2, and can be altered through the choice of a photoresist and related parameters such as the initial thickness of the photoresist and exposure time. The initial thickness of the photoresist was 3.0 µm and 0.8 µm for the calibration curves of Fig. 1 and Fig. 2 respectively. To transfer a multilevel resist structure of DOE into quartz through a dry etching process, the relative etch rate between photoresist and quartz substrate can be so chosen to achieve the final needed etch depth 3 to 6 times that in the resist. Therefore for the fabrication of DOE in quartz a surface height variation of 350 nm in the resist results in a depth modulation in quartz of up to 2100 nm. Fig. 3 exhibits the absorption spectra of LDW-HR plates-type I, -type II and -type III. The optical density at the wavelength of optical lithographic exposure tool, e.g., 436 nm (G line of mercury arc) is 1.4, 2.4 and 3.0 for type I, type II and type III plates respectively. The corresponding optical density at 365 nm (I line) is 1.0, 1.6 and 2.0 for type I, type II and type III plates respectively. The optical density at 405 nm (H line) is 1.2, 2.0 and 2.7 for type I, type II and type III plates respectively. The optical density of type III plates exceeds 3.0 in the spectral range of 430 nm to 615 nm. Depending on the photoresist and the exposure tool of choice in the photolithographic process of producing DOEs, one can select among type I, type II and type III of LDW-HR plates for the required optical density at the wavelength of lithographic exposure tool. LDW-glass photomask blanks having optical density of any specified value that is different from those of type I, type II and type III plates are available on special order. The increased optical density values from type I to type II to type III plates are due to an increased thickness of the colored glass layer. |

LDW-HR plate-type I has a larger write-latitude than the type II plate which in turn has a better write-latitude than the type III plate. LDW-HR plates are recommended for write-wavelengths shorter than about 900 nm and is also good for a write beam using CO2 laser at 10.6 *m wavelength. For write-wavelengths longer than about 750 nm, LDW-IR plates are preferred. Fig. 4 shows the absorption spectra of LDW-IR plates-type I, type II and type III. The optical density values at the wavelength of optical lithographic exposure tool, e.g. 436 nm are 1.2, 1.8 and 2.6 for type I, type II and type III plates respectively. The corresponding optical density values at 365 nm are 1.4, 1.8 and 2.1 for type I, type II and type III plates respectively. The optical density values at 405 nm are1.2, 1.8 and 2.4 for type I, type II and type III plates, respectively. The optical density of type II plates exceeds 3.0 in the spectral range of 570 nm to 805 nm. The optical density of type III plates exceeds 3.0 in the spectral range of 490 nm to 915 nm. Depending on the choice of photoresist and lithographic exposure tool, one can select among type I, type II and type III of LDW-IR plates for the required optical density at the wavelength of optical lithographic exposure tool. LDW-glass photomask blanks having optical density values that are different from those of type I, type II and type III plates are available on special order. The increased optical density values from type I to type II to type III are due to an increased thickness of the colored glass layer. The type I plate has a larger write-latitude than the type II plate which in turn has a better write-latitude than the type III plate. Due to the effect of the erasure-threshold intensity, there is no soft line-edges in the laser direct write patterns recorded in LDW-glass plates using a focused laser beam with a Gaussian intensity profile. The recorded spot size in LDW-glass plates is substantially smaller than the size of the airy disc of the focused laser spot in air. Moreover, the grain size of coloring specks of silver in the LDW-glass is of atomic dimension, and LDW-glass plates have no graininess. Submicron features were recorded in LDW-glass plates using laser beams of various visible wavelengths focused with an objective lens which has a numerical aperture as low as 0.25.

|

|

Direct Fabrication of Phase DOEs in LDW Glass |

Company | Technology | Products | Online Help | Contact